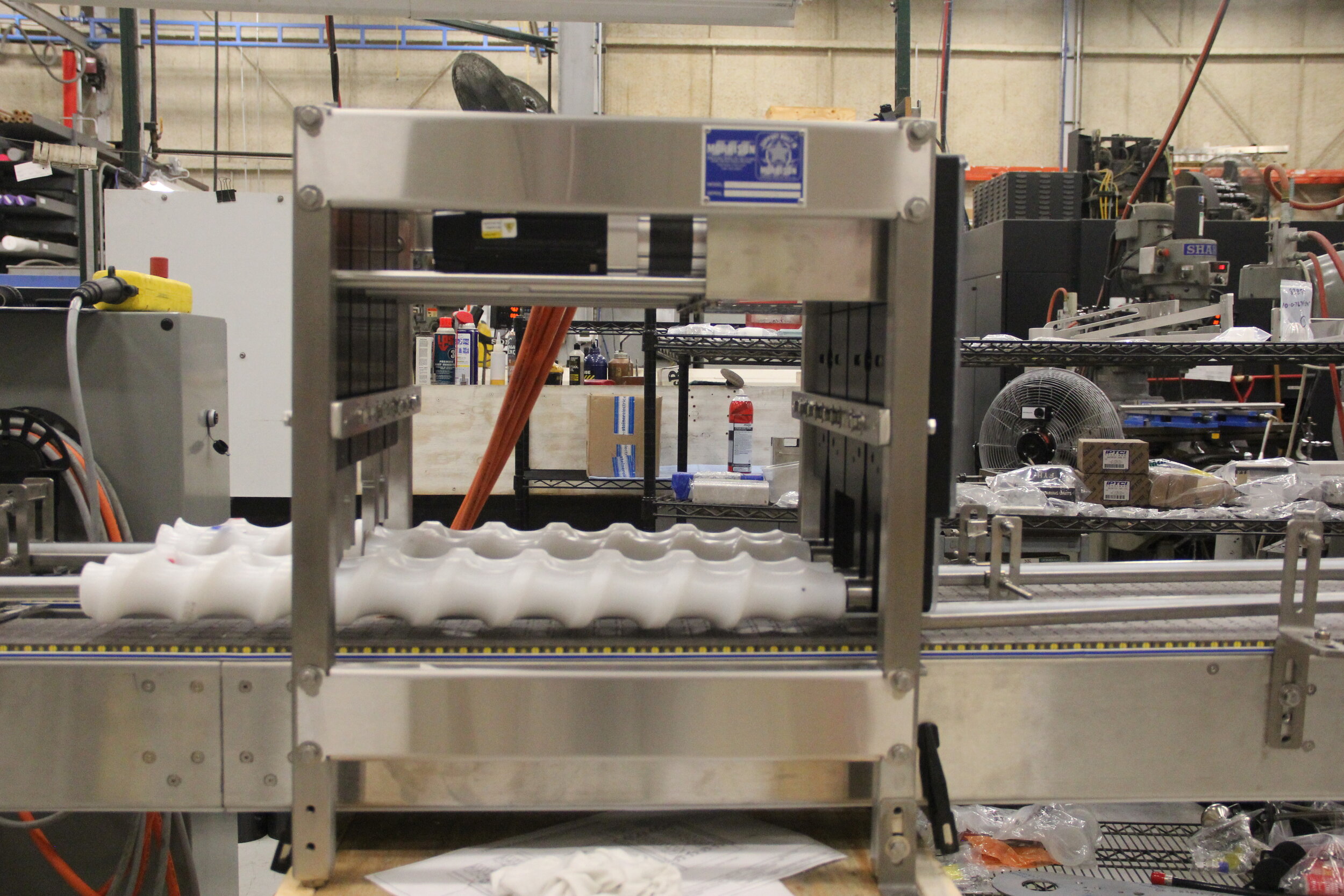

Dual Lane Metering Custom Drive Assembly for Mini Bottles

Alcohol Handling Solution

Case Study: Morrison Dual Lane Metering Custom Drive Assembly

INDUSTRY: Alcohol | OPERATING SPEED: 350 CPM PER LANE / 700 CPM TOTAL

CONTAINER: 50ml + 100ml Miniature Liquor Bottles

Customer Container Handling Challenge: Our customer had 2 lanes of product that needed to feed a flight bar to create a variety of pack patterns for 50ml and 100ml miniature liquor bottles.

Morrison Solution: We provided a dual lane and dual timing (feed) screw custom drive unit that accepts full and capped miniature liquor flasks from a backlog and discharges them to a specific pitch that feeds the flights back, effectively creating the designated pack pattern for that production run. Each lane runs 350 containers a minute, which generates 700 containers in total a minute at output of the Morrison system.

This system was servo driven and programmed into the customer’s existing line controls.

The timing screw design includes interpolated root diameters which means there is no need to adjust the system when running different container sizes. By eliminating the grouping screw and using a 1-up screw instead, Morrison drastically reduced the amount of timing screws needed on this system while still providing for adaptability to various pack patterns.

Construction: Black Anodized Aluminum

Pack Patterns Created:

50ml

2x2

2x5

100ml

2x2

2x6