Industry Spotlight: Alcohol (Beer + Wine + Spirits)

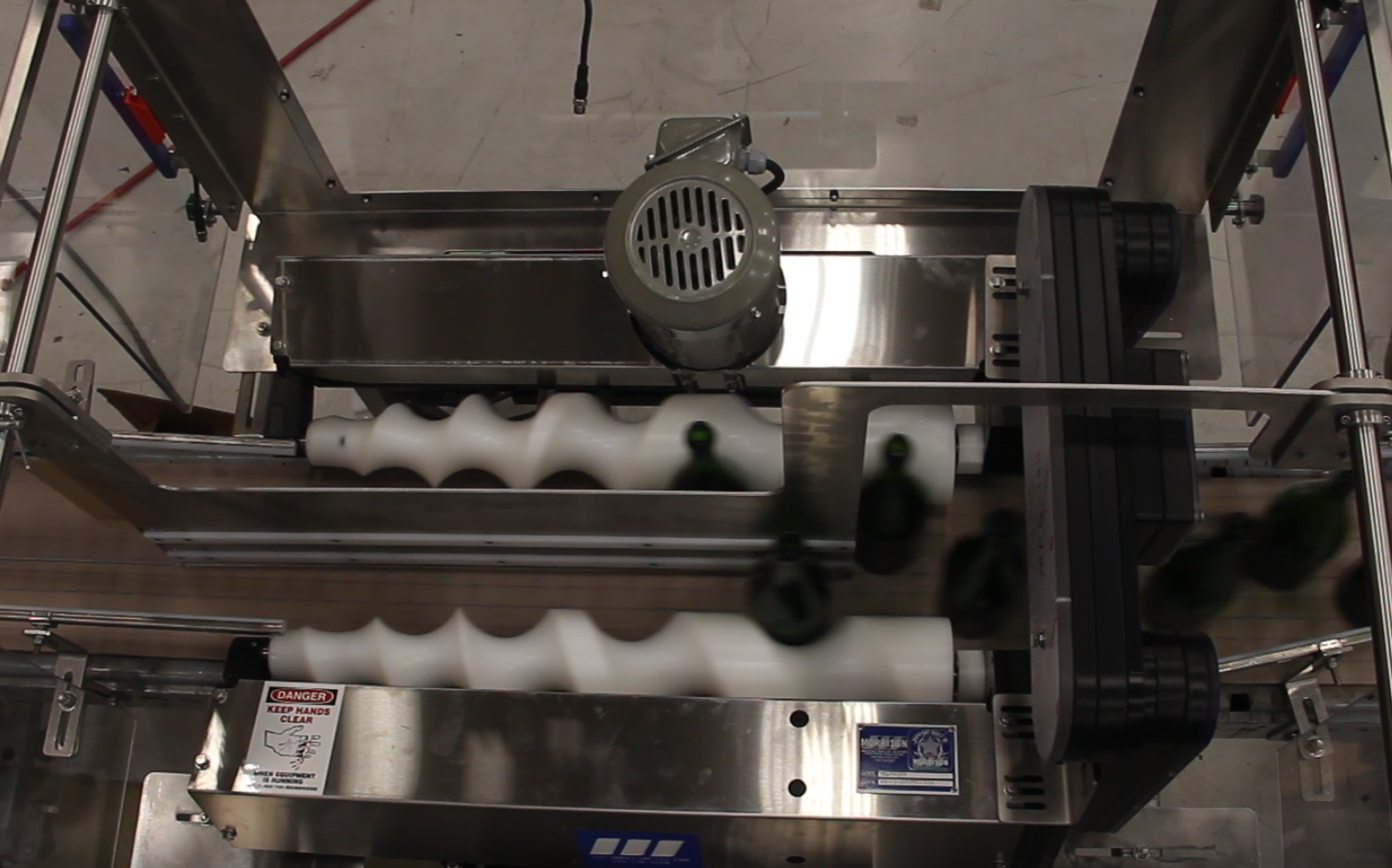

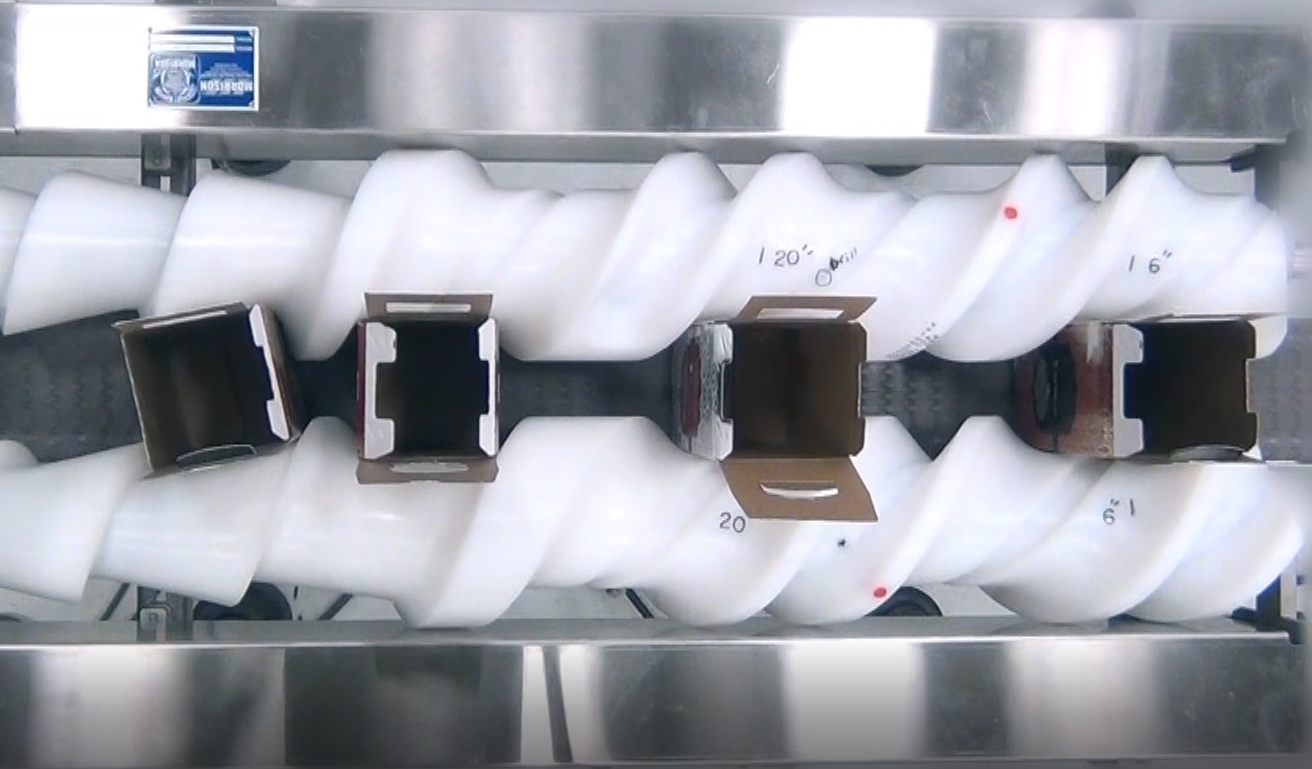

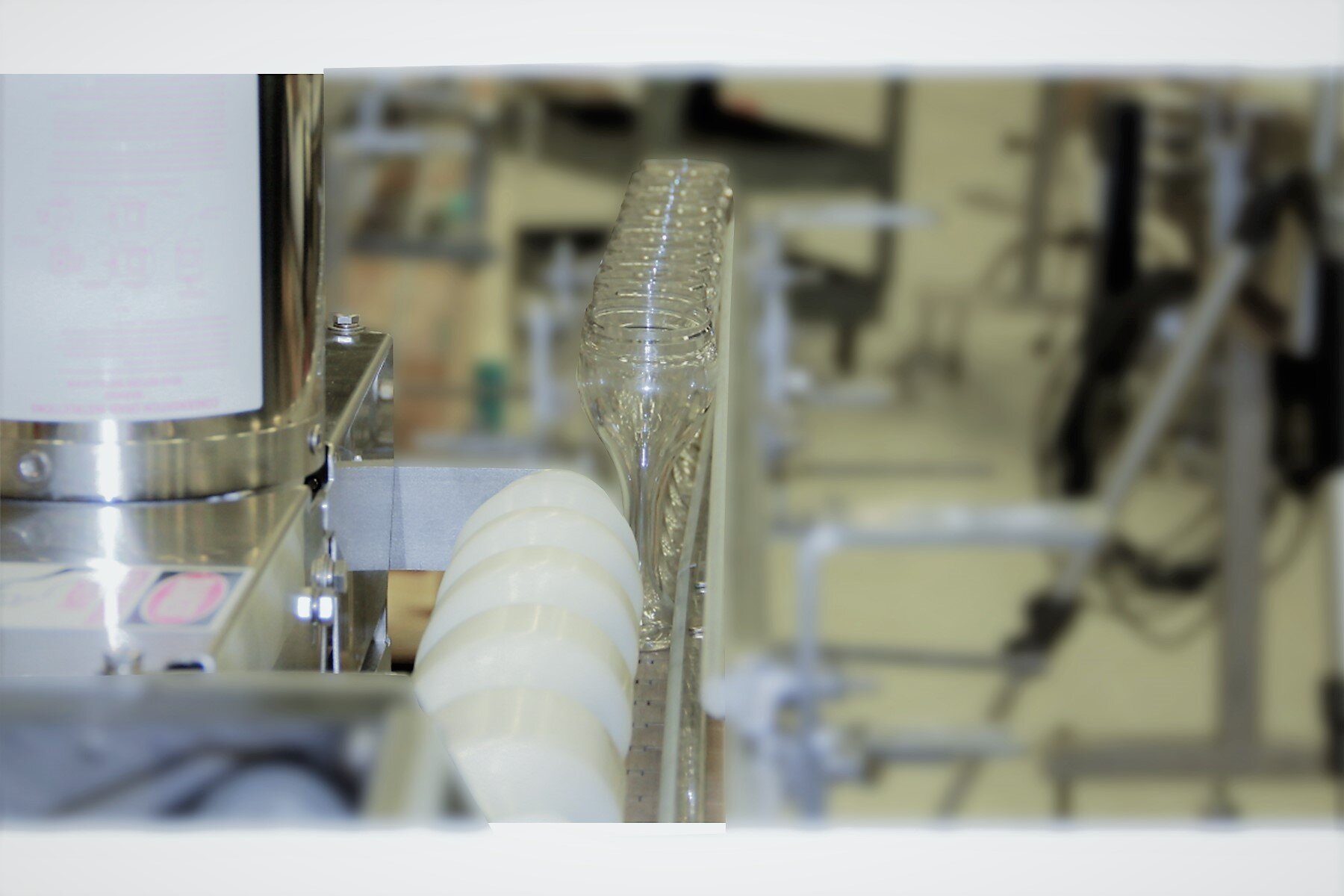

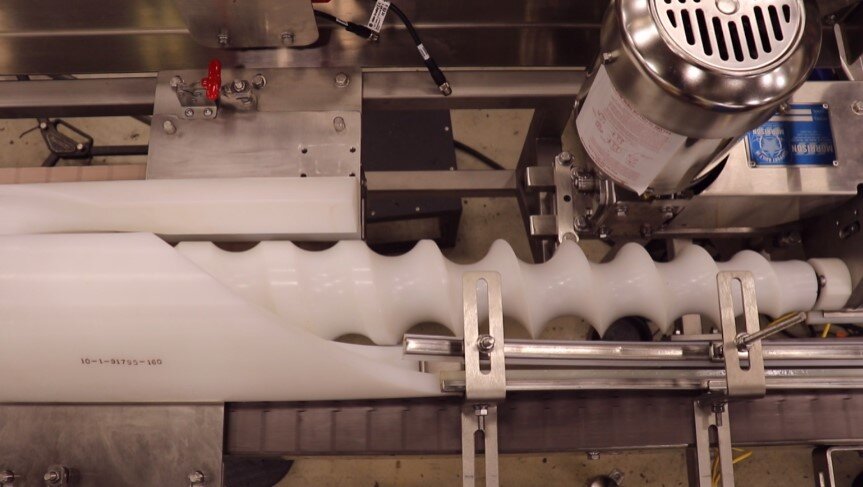

Wine, beer, and spirits go through a variety of packaging applications before making it on shelves. Morrison is known for its knack of presenting alcohol containers to increase your up time and minimize breakage with a variety of our handling solutions. Glass bottles are heavy and cans are light so you need nimble solutions that can work with all container types that can prove ROI. From high speed operations to minimize breakage or positioning under fillers for boxed wine, our engineers have proven excellence in handling your wine, beer, and spirit bottles and cans so they can be filled, capped, labeled, and packaged with accuracy and success.