Industry Spotlight: Dairy

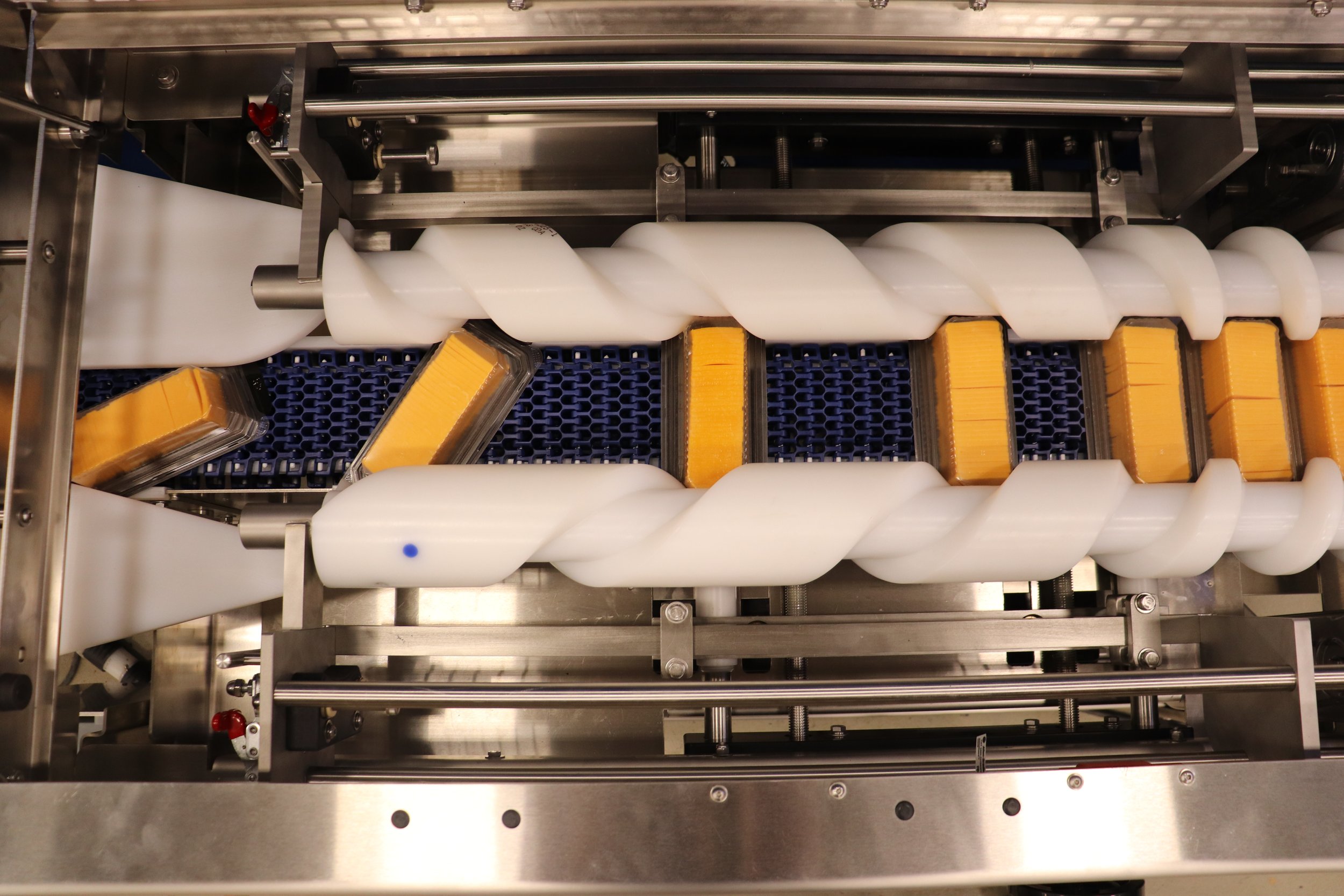

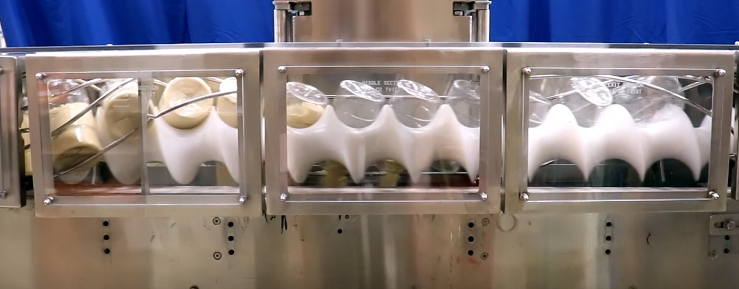

Dairy processors and packagers need to meet the highest standards of cleanliness. At Morrison, we know there are many challenges associated with dairy packaging, but our engineers believe container handling shouldn’t be one of them. With our high washdown rated systems, you can utilize timing screw and change parts technology in order to move your dairy containers for any packaging application. From difficult gable-top milk cartons to butter and cream cheese rounds and squares, we will design and manufacture the perfect custom application to improve your plant efficiencies and consistency in container movement.

Our solutions provide flexibility for container design, which is a must for dairy manufacturers that need modular adaptability to adhere to marketing changes to consumer taste. We can design new screws to accommodate packaging changes and provide ease of changeover when it comes to fulfilling consumer preferences all in the same production line. We’ll work to be your total solution partner that can minimize downtime and increase productivity with simple, quick changeovers all at cost-effective pricing that has a high ROI.