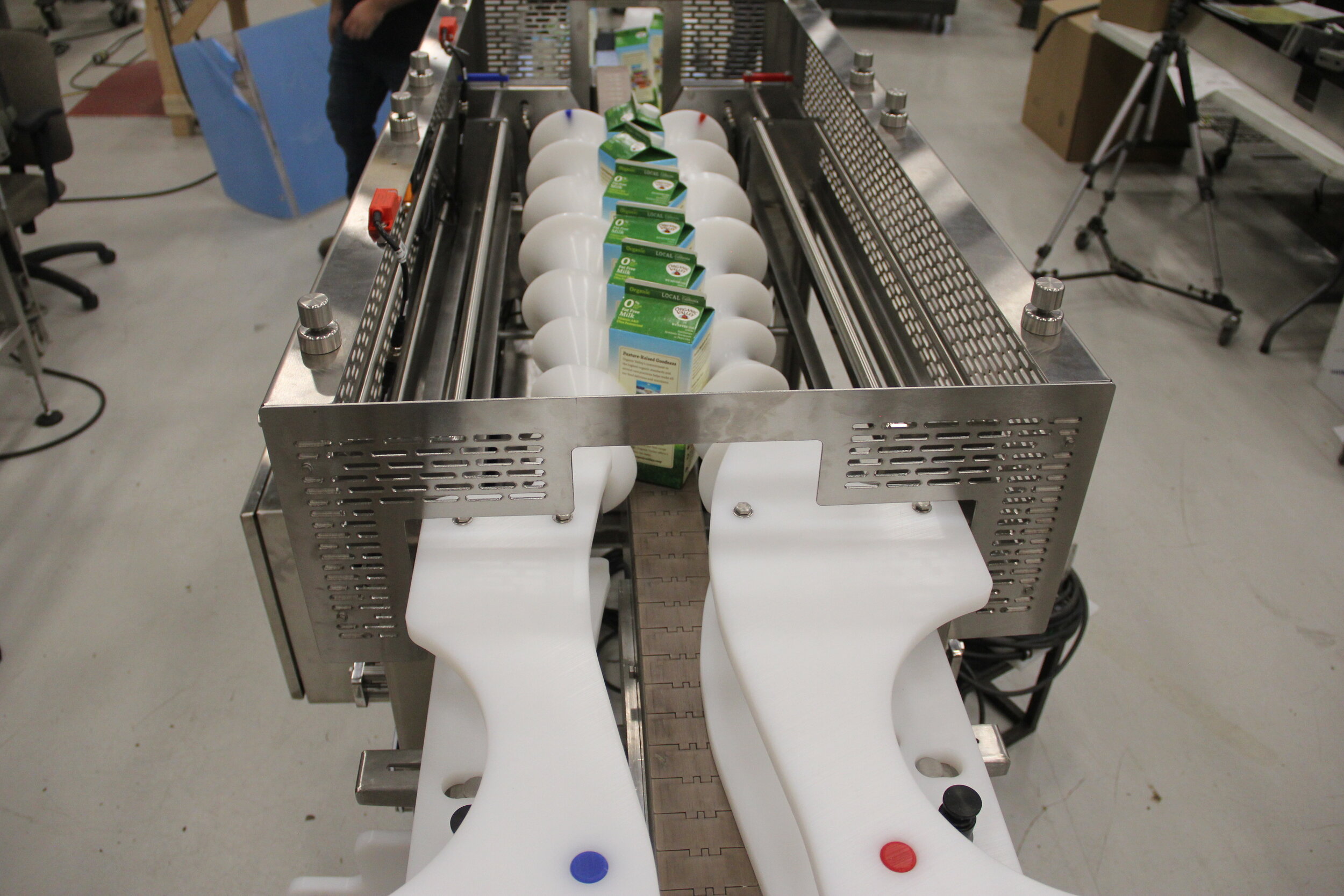

Dual Turning Custom Drive Assembly

Dairy Handling Solution

Case Study: Morrison Square Carton Turning Custom Drive Assembly

INDUSTRY: Dairy | OPERATING SPEED: 70 CPM | CONTAINER: Gable Top 1/2 Gallon Milk

Customer Container Handling Challenge: Needing a solution to turn milk cartons automatically after they leave a filler for the next stop in the production line, this customer came to Morrison to provide a timing screw solution. Timing screws provide the same accuracy every single time, but square milk cartons are a notoriously difficult container to handle through screws. To up the challenge, they needed one solution to turn the containers 90 (clockwise and counter-clockwise), 180 degrees or simply bypass turning as the plant footprint would only allow for one system.

Morrison Solution: Our engineering expertise utilized a shingle infeed design to accept the container without damaging it and then begin to turn the containers 90 or 180 degrees. Bypass screws were also provided in the event no turning is needed. The system allowed for 90-degree clockwise rotation, 90-degree counterclockwise rotation, 180-degree rotation or no rotation. After the containers left the system, they continued down the production line for packaging. Dual timing screws with shingle infeed positively accept the container and consistently turn them appropriately. Infeed guide assemblies accept the containers smoothly while large outside diameter screws fully capture the container during the process resulting in a very smooth turn.

Construction: Stainless Steel High Washdown