Morrison Rotary Nutraceutical Orienting System for Filling

Pharmaceutical Solution

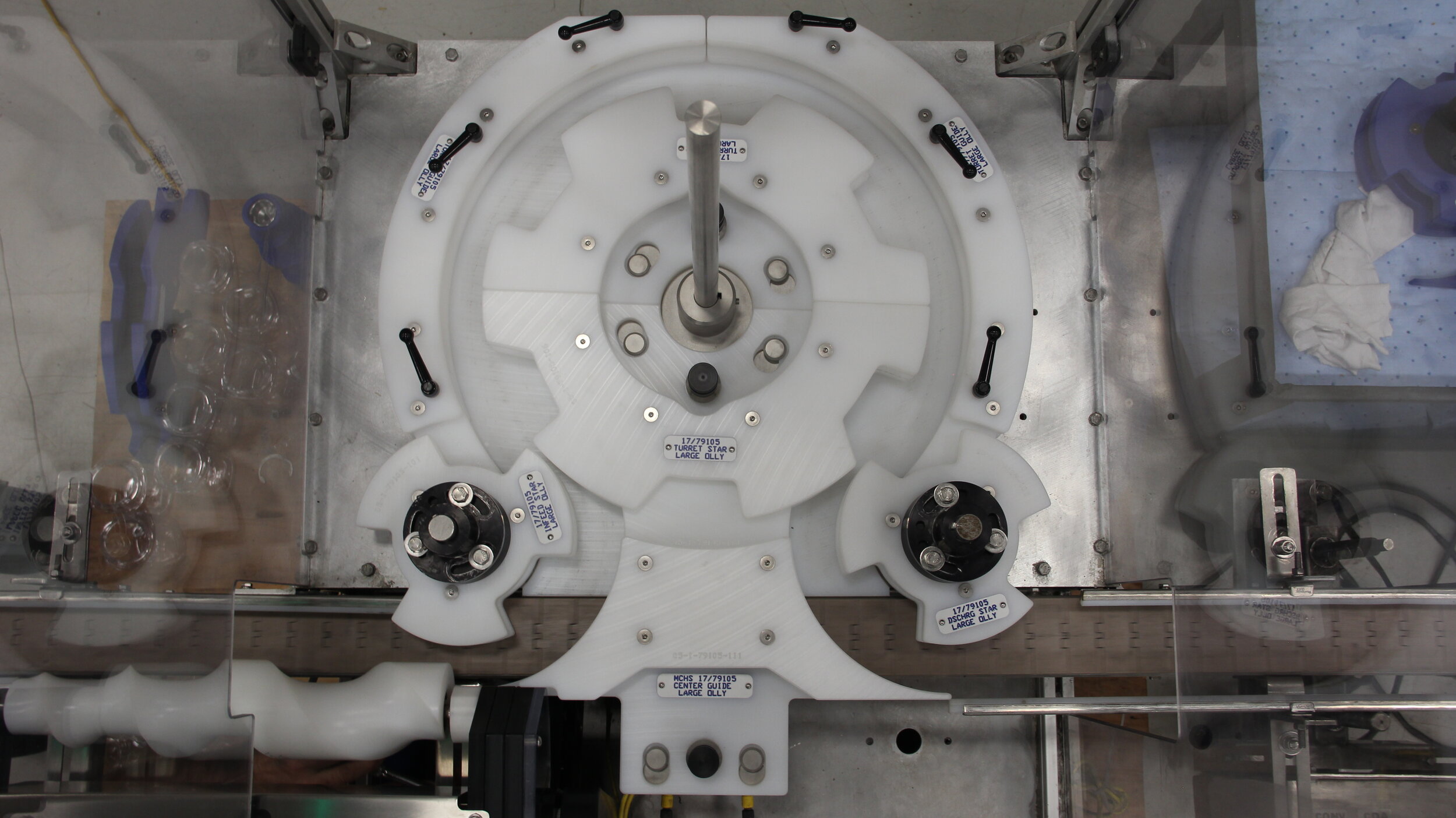

Case Study: Morrison Rotary Nutraceutical Orienting Feed Screw and Stars and Guides

INDUSTRY: Pharmaceutical | OPERATING SPEED: 150 CPM

CONTAINER: 5 oz + 7 oz Square Gummy Vitamin Bottles

Customer Container Handling Challenge: This contract packager was hand filling vitamin gummies, which was a timely process.

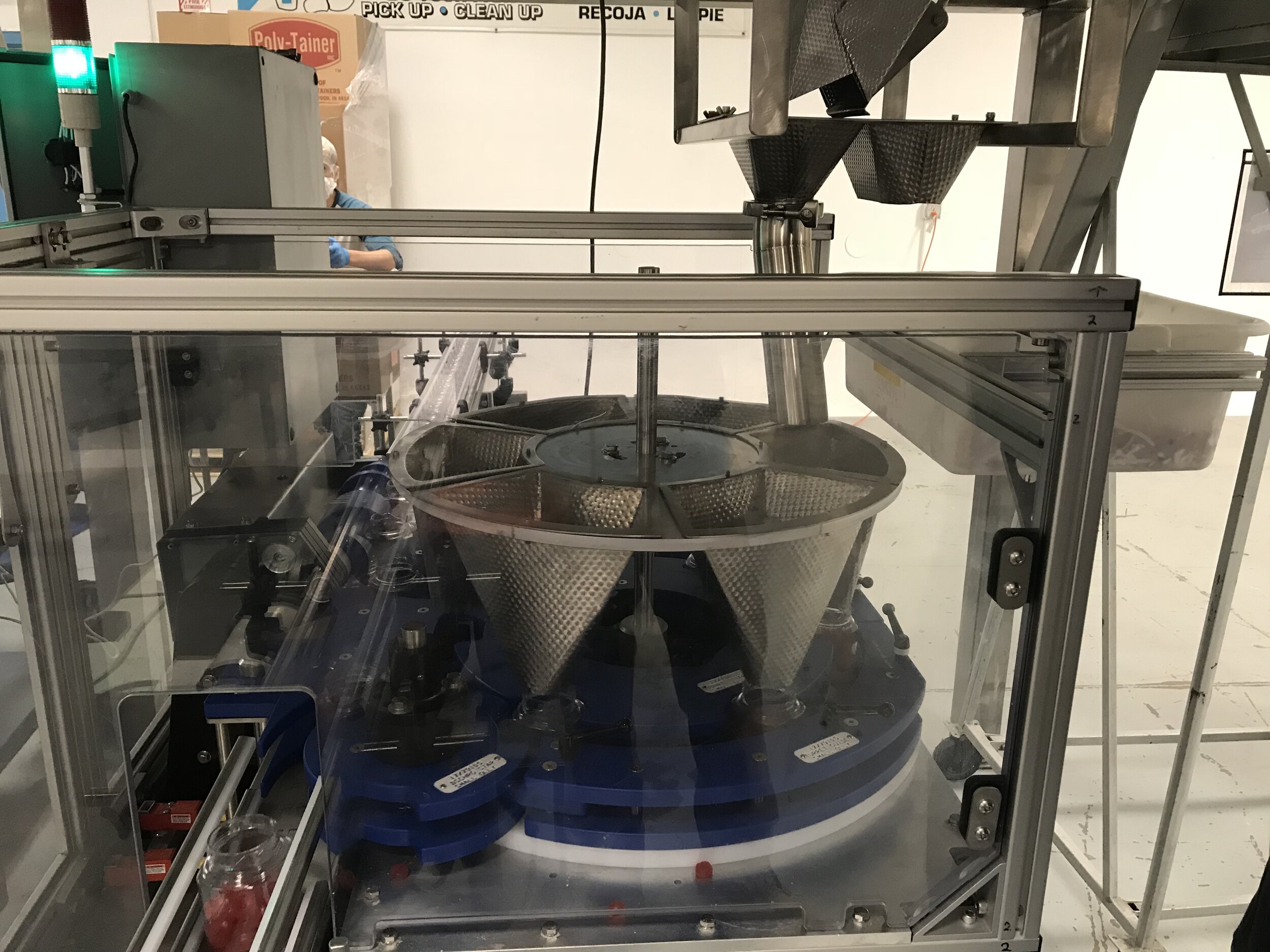

Morrison Solution: We used our orienting expertise to design a rotary orienting system that would position under a customer-supplied filler, presenting the containers at perfect pitch under the rotary filler heads that are fed by a load scale.

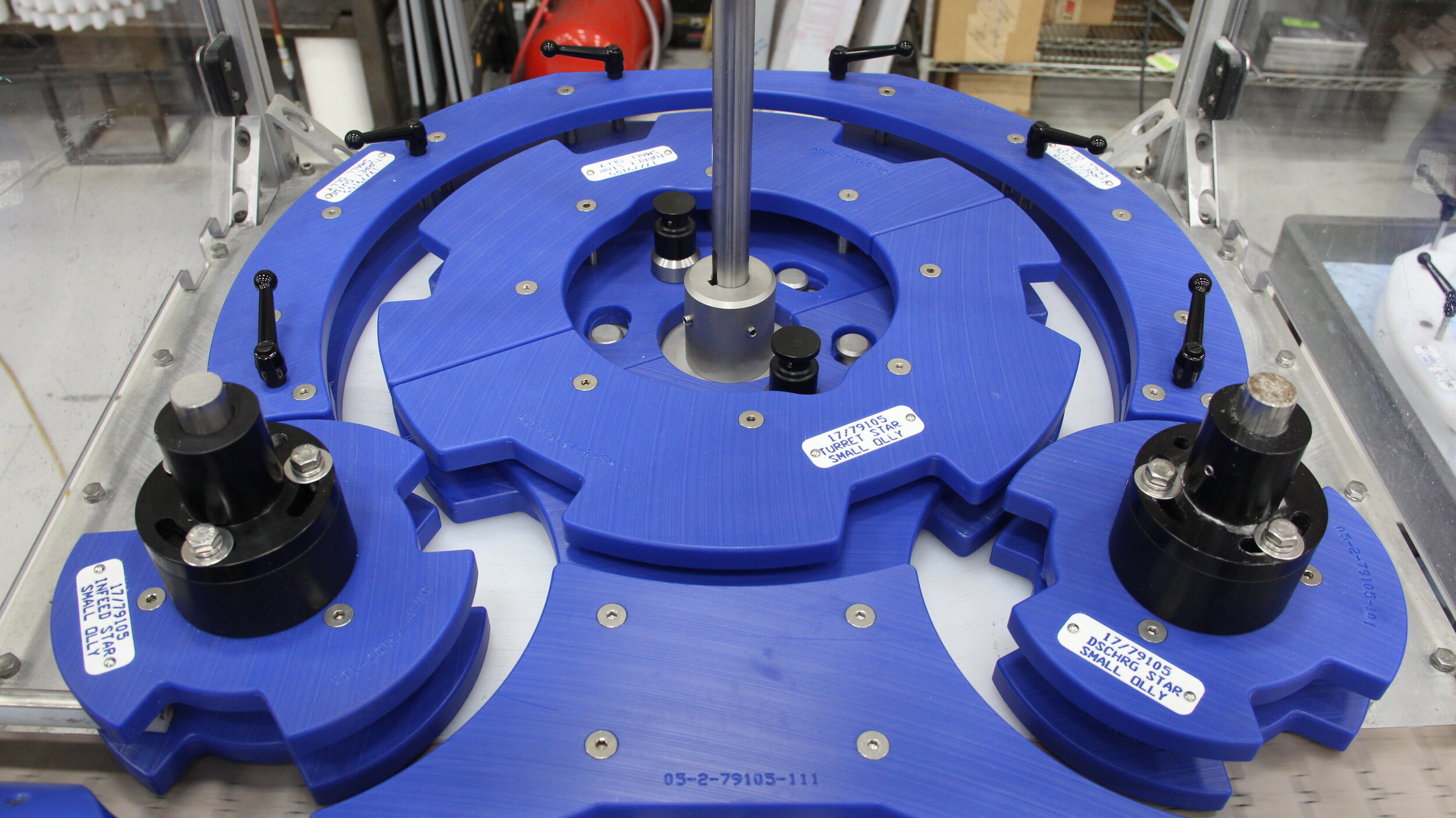

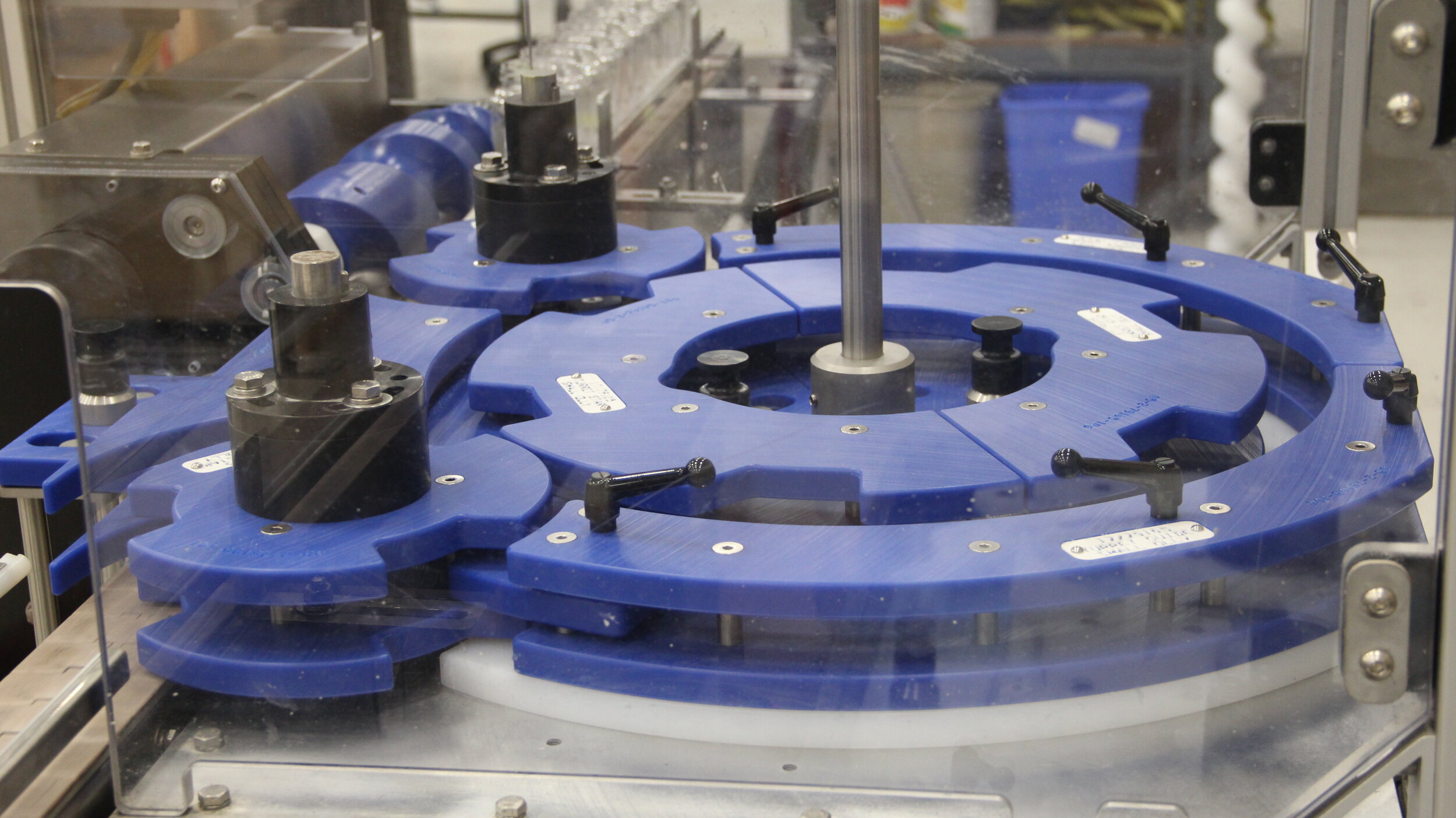

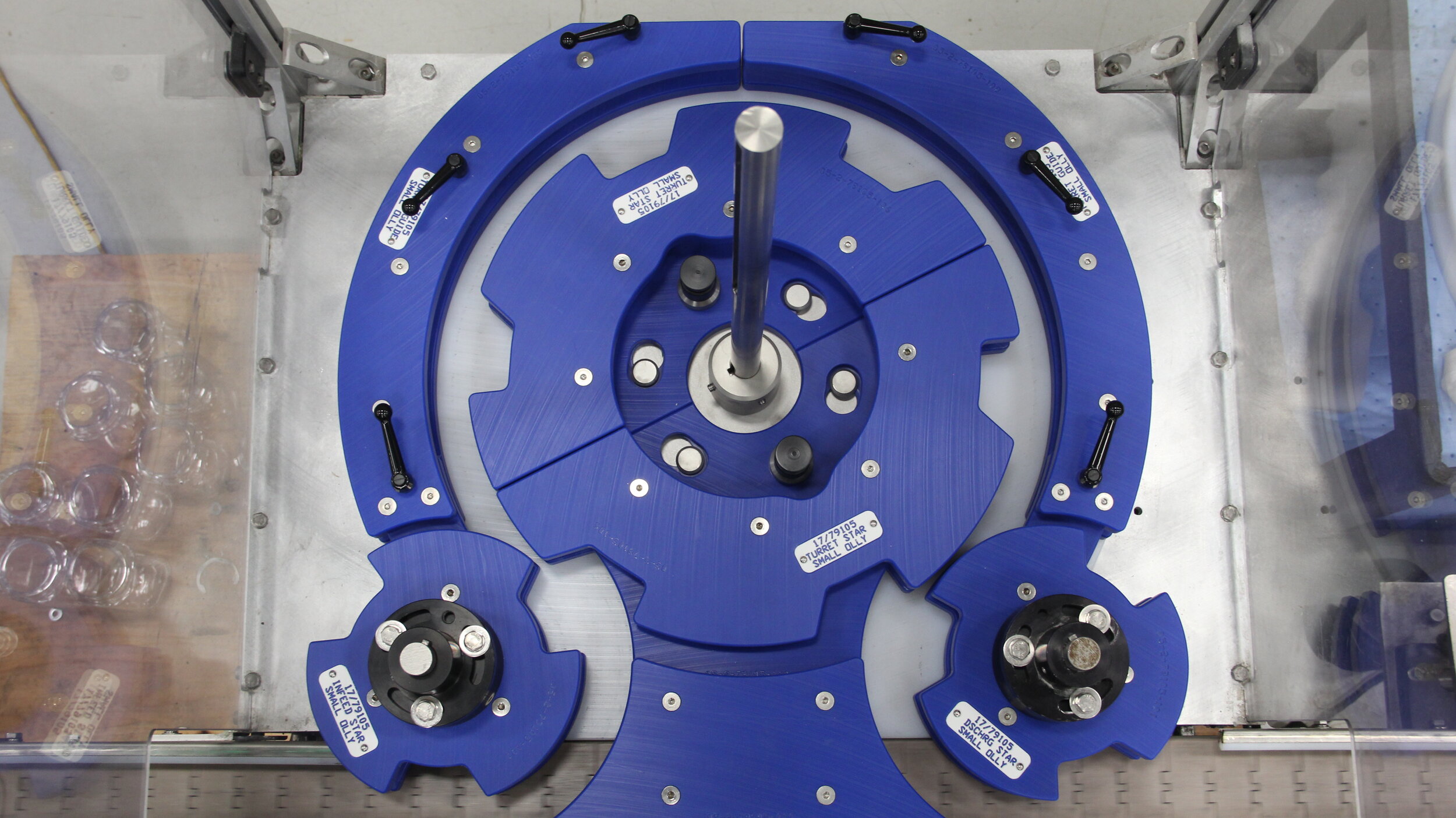

The containers are placed at pitch through a timing screw (feed screw) into an infeed star wheel and then travel around another star while followed by the filler heads, ultimately exiting to a capper. Morrison change parts (stars and guides) positively handle the container throughout the entire process.

This rotary design allows for continuous motion while filling, which eliminates the laborious hand-filling process and allows more throughput and finished product to be packaged daily. The design of the Morrison stars and screws into the existing system allows upgrades for changed packaging so this system can evolve with customer marketing.

Construction: UHMW

Benefits of Rotary Design

Inline and rotary designs both have unique purposes for filling applications. In this case, the rotary design was preferred as it allows a continuous motion for filling, eliminating the start and stop of inline application designs. In the end, this creates more throughput and product per minute.