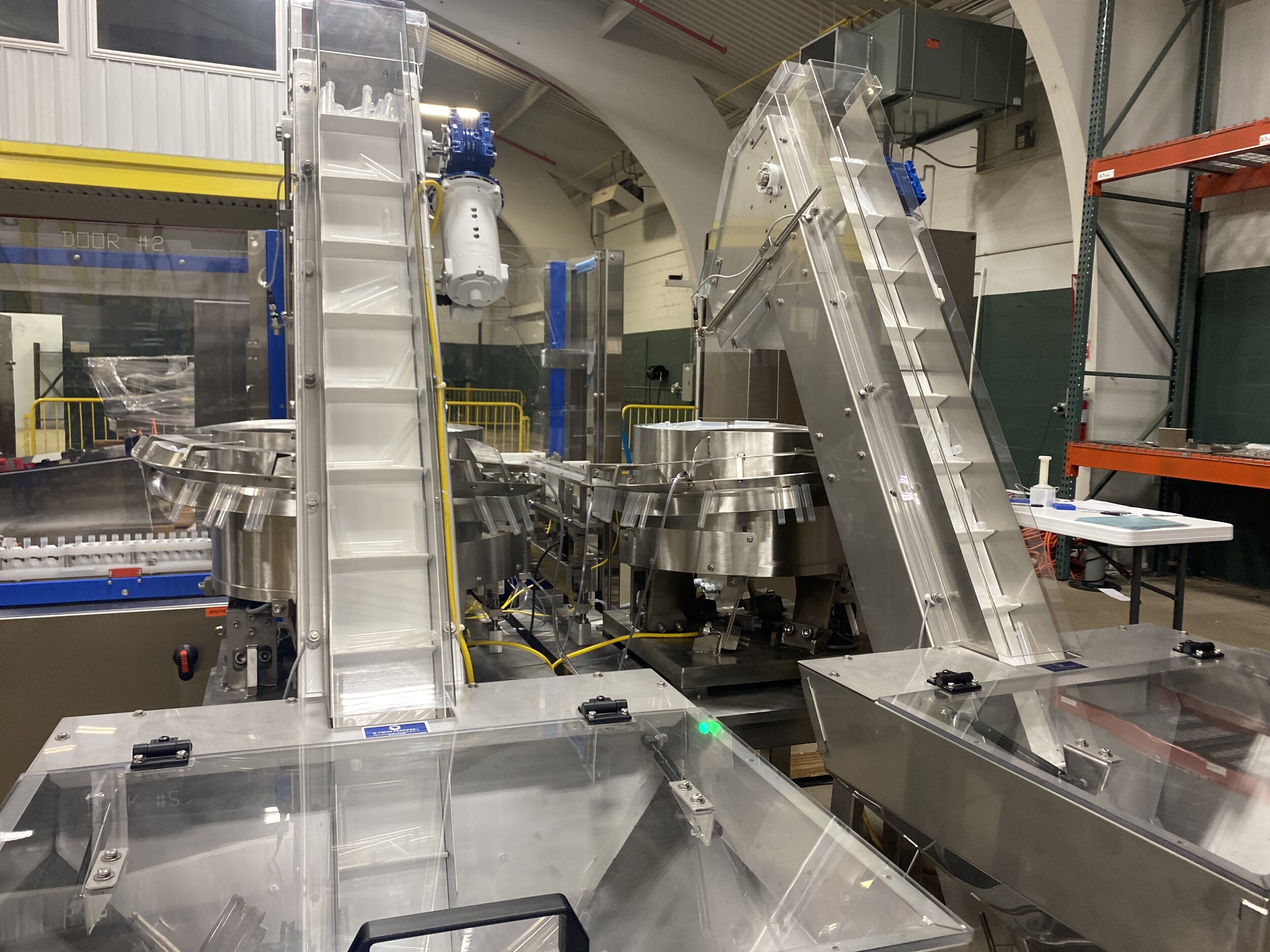

Morrison Stacked Timing Screw Integrated Packaging System

Pharmaceutical Solution

Case Study: Morrison Ramps Up COVID-19 Test Kit Production by 20,000% with Turnkey Solution

INDUSTRY: Pharmaceutical | OPERATING SPEED: 120 CPM

CONTAINER: 15ml Test Tube

Customer Container Handling Challenge: When COVID-19 hit the world by storm, Thermo Fisher Scientific was tasked by the United States government to get as many COVID-19 tests into the market as soon as possible. They needed to be filled, capped, and packaged quickly, to meet Consumer demand, and at the time, the company was only able to manufacture 30 to 50 tests a minute on their current 4 lines.

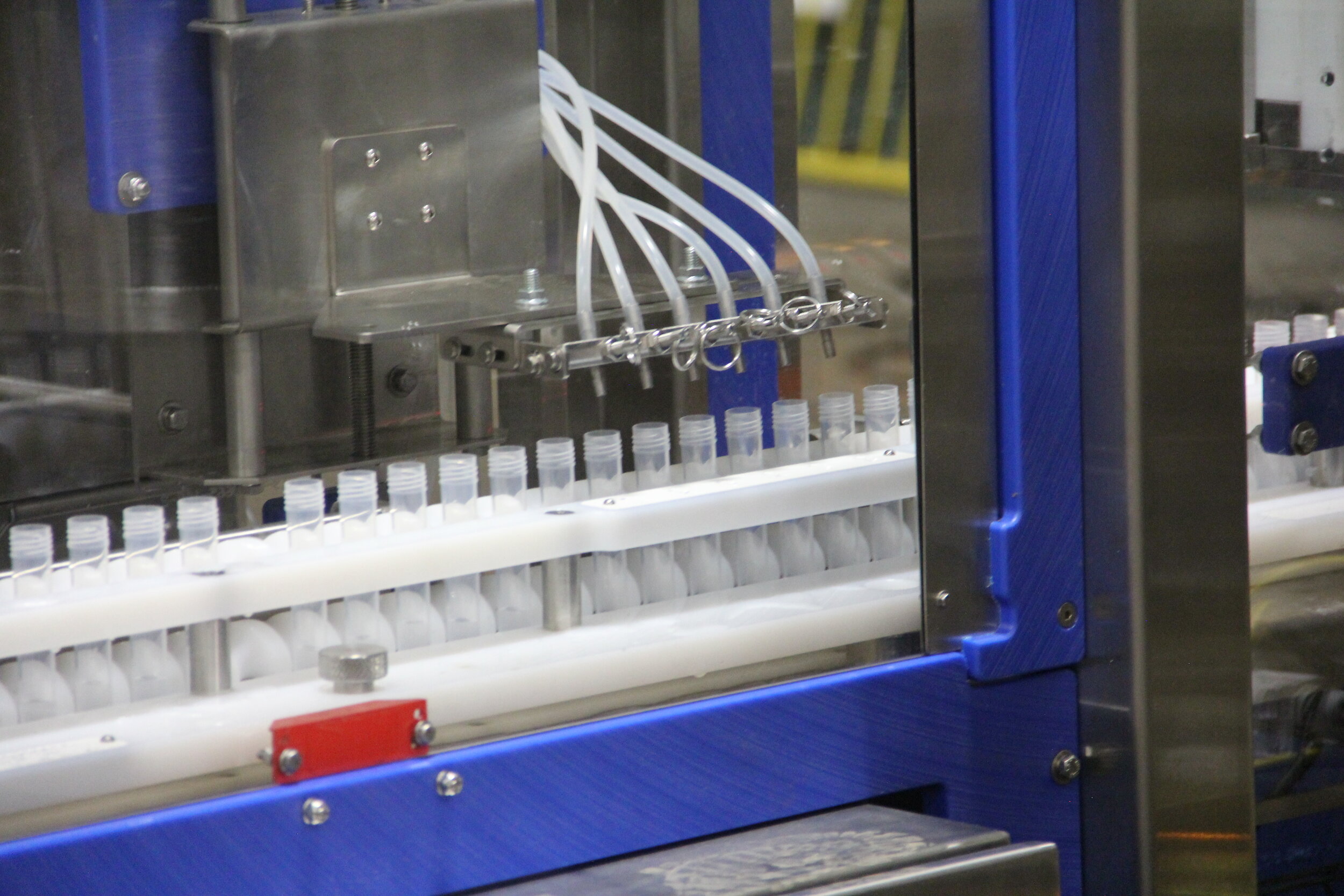

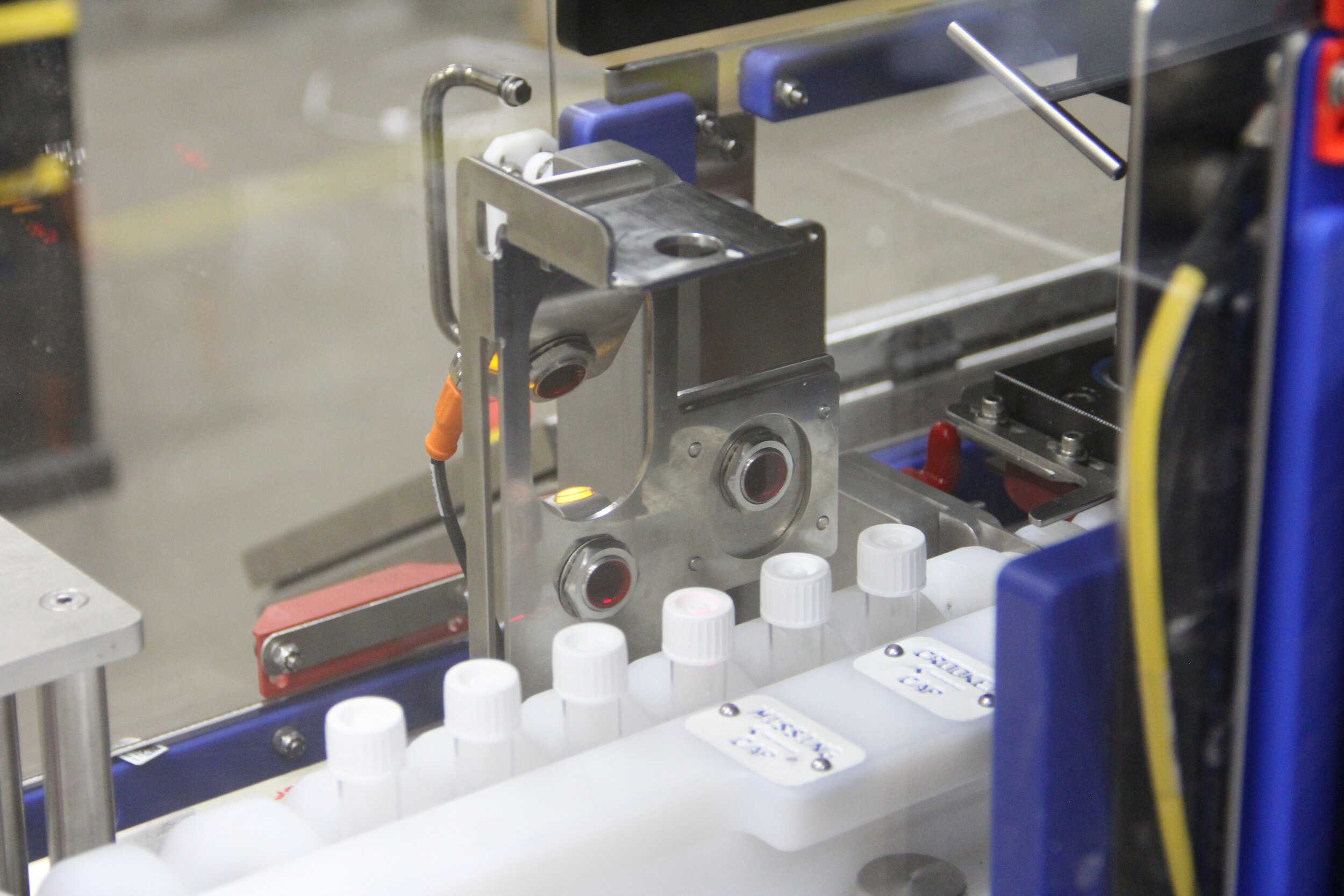

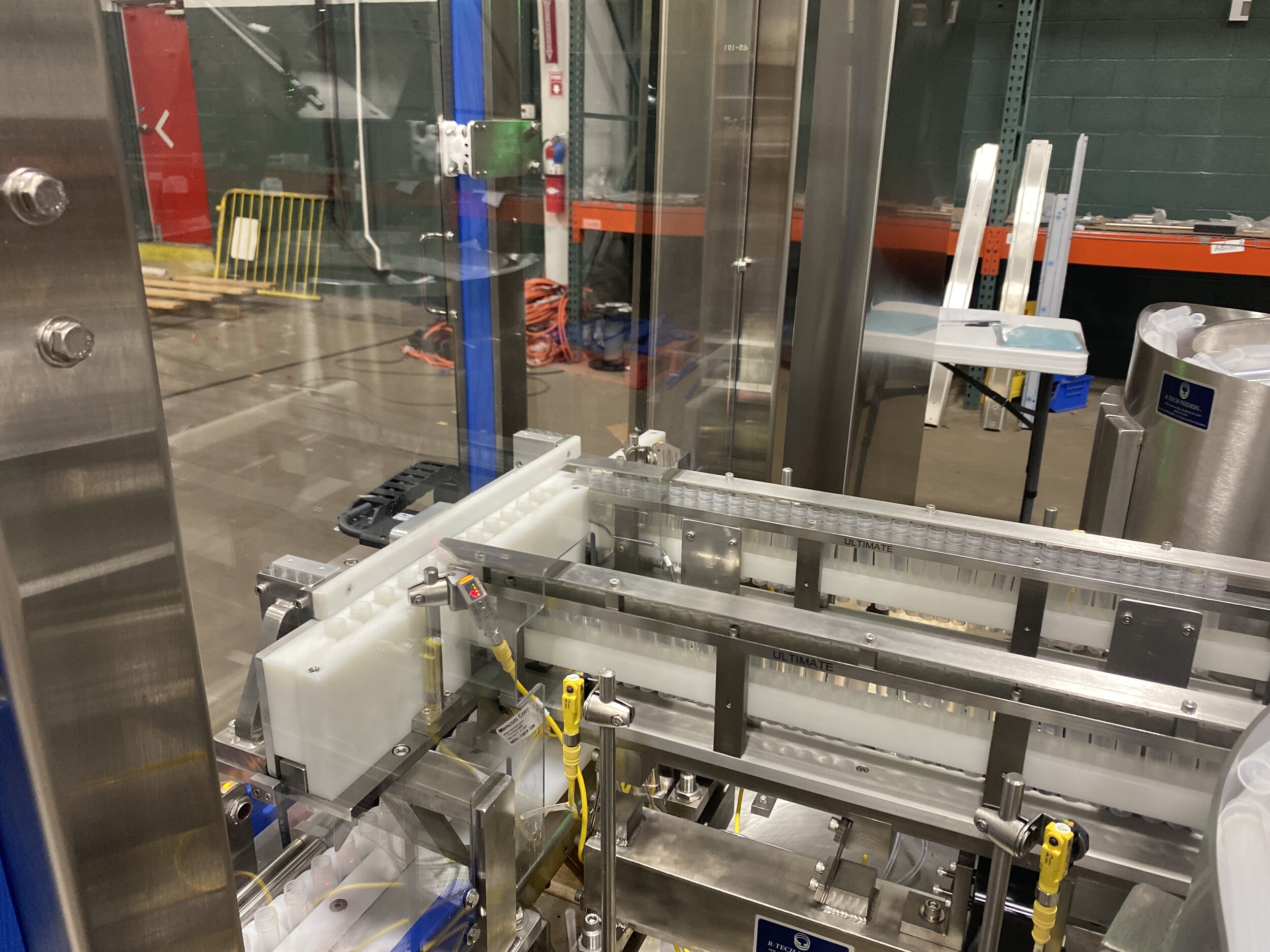

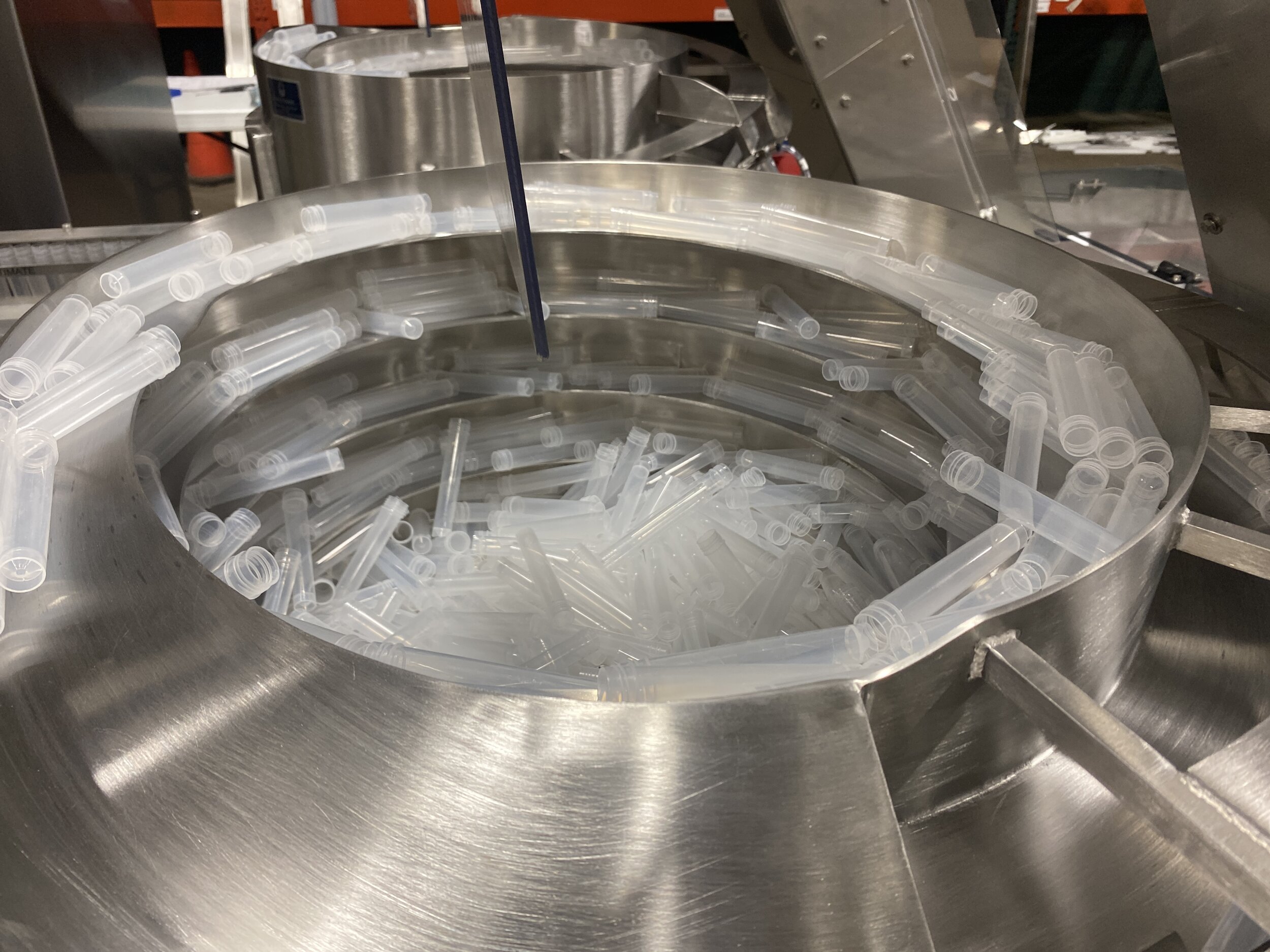

Morrison Solution: Each system has been engineered by Morrison’s Head of Engineering Ryan Finke to move the test kit through a variety of packaging applications. Taking the tube through unscrambling, filling, capping, and presenting for final packaging, this system can produce 120 tubes a minute, improving the originally time-consuming hand-fill production drastically.

The timing screws positively control the container throughout the entire process, accepting them from the sorter and moving them along with dwell for filling, indexing for capping, and laying down on an exit conveyor for final packaging. By bringing the speed up from 30-50 CPM to 120 CPM per line, the company ordered a total of 16 lines to be integrated in plants state side and internationally, helping to meet the demand of COVID-19 testing.

Each system is capable of producing 130,000 test kits a day.

This engineering and manufacturing need was presented to Morrison in March, allowing us to exercise their custom container handling solution expertise and bring a years-long engineering feat to market in just under six months.

MORE SYSTEM DETAILS

Construction: Stainless Steel

Output Increase with Morrison System:

Previously, the customer only had four lines with outputs of:

Line A - 30 CPM

Line B - 50 CPM

Line C - 45 CPM

Line D - 45 CPM

The Morrison project produced 16 lines, all running at 120 CPM.

Output Numbers:

120 CPM for Each System

130,000 Kits a Day Per System

2,080,000 Kits a Day When All 16 Systems in Operation