Variety Pack Sorting and Filling System

Beverage Handling Solution

Case Study: Morrison Custom Variety Pack Sorting and Filling Integrated System

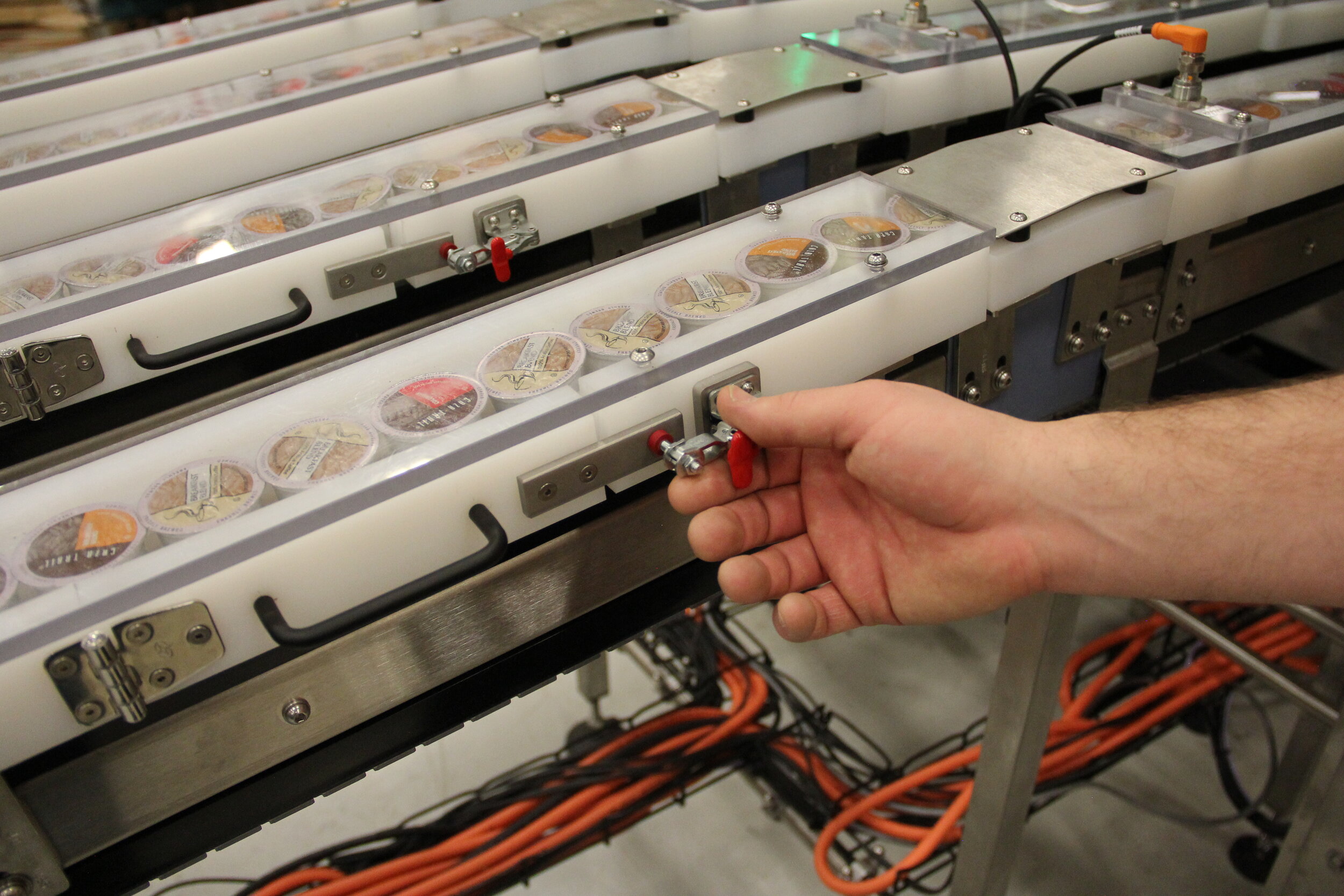

INDUSTRY: Beverage | OPERATING SPEED: 250 CPM per lane

CONTAINER: Single Serve Coffee Pod

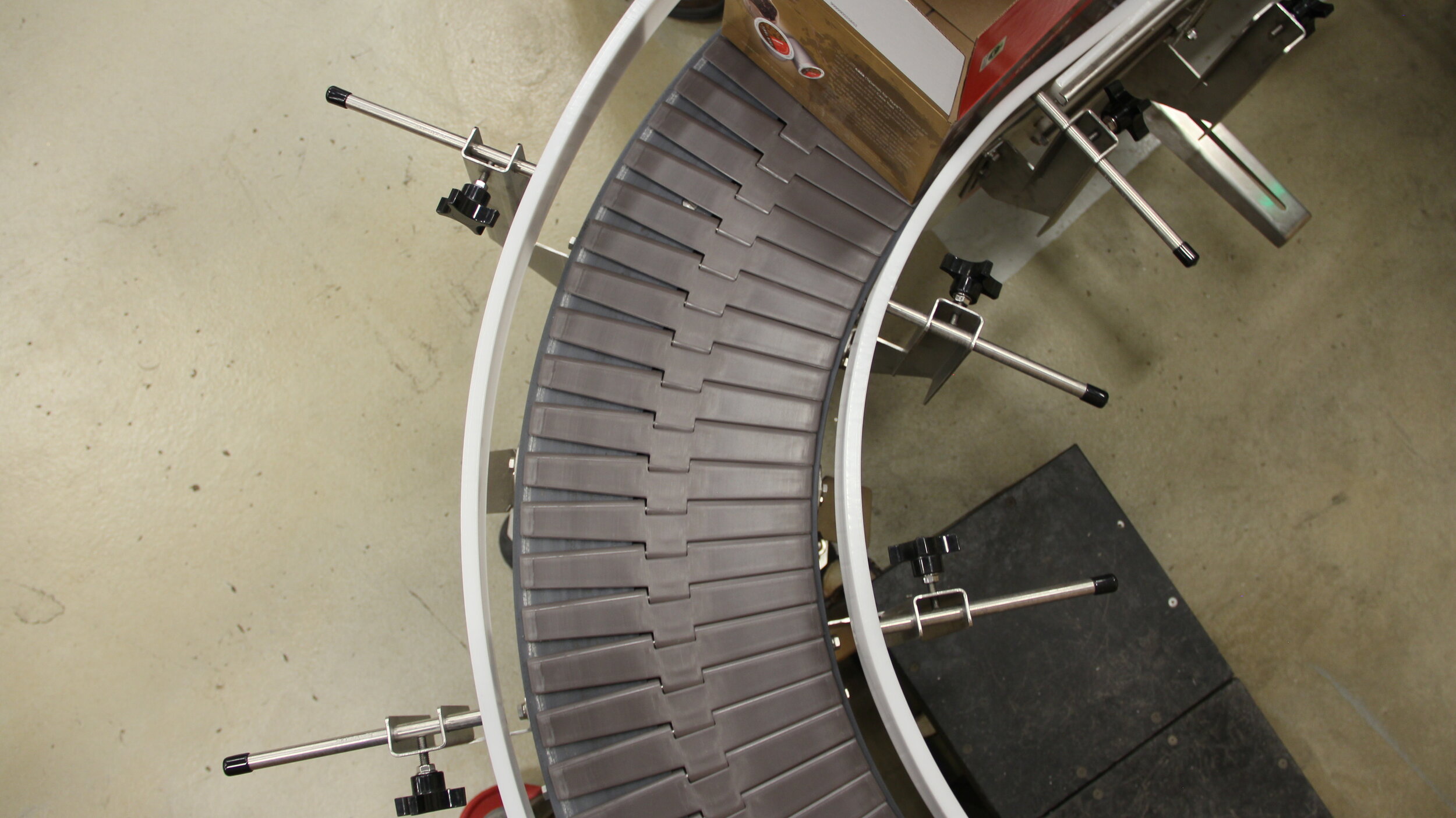

Customer Container Handling Challenge: Our customer approached us needing a full integration system for single serve coffee pod variety packs. They needed to be able to sort, fill, and prep for final packaging all with one system, and the system needed to provide for different pack patterns within the same line.

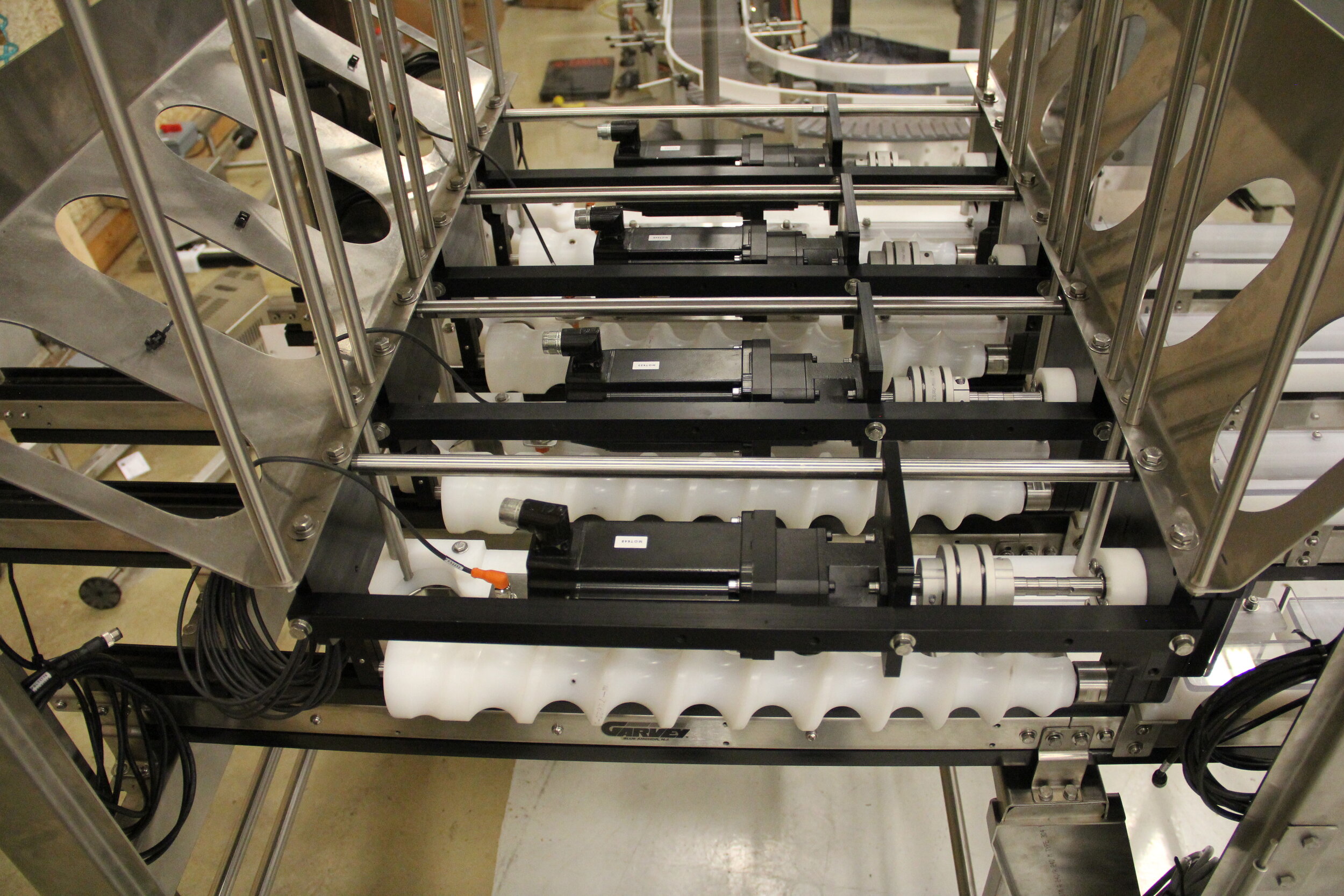

Morrison Solution: Coffee pods are sorted into four lanes and metered with timing screws. As the screws end, they are dropped into the boxes, but there much controls technology behind the scenes, allowing for adaptability in the packs.

Morrison’s customized HMI allows operators to choose how many containers from each lane will be dropped into the variety pack, allowing adaptability and versatility within the packaging line. Sensors confirm how many containers drop into the box, to ensure precise fills for quality control. A shaker is then used after pods drop to settle product below the fold line to continue onto final packaging, fully automating the process of filling variety pack boxes with adaptable pack patterns.

Construction: Black Anodized Aluminum